Portable Doppler Flow Meter PDFM 5.1

- Clamp-on Ultrasonic Transducer

- Handheld Meter with large backlit LCD Display and Totalizer

- Internal Battery and/or AC Powered

- Built-in 5-Key Calibrator

- 300,000 point Data Logger

- USB Output and Windows software

- 4-20mA Output

- Rugged, watertight Carry Case

- Description

- Reviews (0)

- Specifications

- Brochure

- User’s Guide

- How It Works

- F.A.Q

Product Description

- Clamp-on Ultrasonic Transducer

- Handheld Meter with large backlit LCD Display and Totalizer

- Internal Battery and/or AC Powered

- Built-in 5-Key Calibrator

- 300,000 point Data Logger

- USB Output and Windows software

- 4-20mA Output

- Rugged, watertight Carry Case

It’s ideal for flow troubleshooting, balancing and checking performance of permanent flow meters. The new PDFM 5.1 is fast and easy to operate – you can mount the sensor on the outside of a pipe in less than a minute. Use the built-in keypad and calibration menu to set up the flowmeter for your application. The PDFM 5.1 works on any liquid containing bubbles or solids and is recommended for “difficult liquids” like wastewater, slurries, sludge, chemicals, viscous liquids and abrasives. Measures flow through most metal and plastic pipes including PVC, ductile iron, carbon steel and stainless steel.

The Greyline PDFM 5.1 is AC/DC powered with built-in NiMH batteries and external charger. With its 4-20mA output you can use the PDFM 5.1 as a spare transmitter in critical applications. For flow studies and troubleshooting use the built-in 300,000 point Data Logger. Retrieve data logs with ‘Greyline Logger’ software – included free with each PDFM 5.1. Connect the USB output directly to your PC or Laptop to download data logger files.

The PDFM 5.1 includes a non-intrusive Doppler ultrasonic sensor for pipes from 1/2″ to 180″ (12.5 mm to 4.5 m) diameter, a stainless steel sensor mounting bracket and clamps, coupling compound and AC charger with a rugged IP67 carry case. It operates up to 18 hours from internal batteries and recharges overnight.

Be the first to review “Portable Doppler Flow Meter PDFM 5.1”

PORTABLE DOPPLER FLOW METER SPECIFICATIONS

SCOPE: This specification covers a portable, ultrasonic Doppler-type flow meter as manufactured by Greyline Instruments, Massena, New York / Long Sault, Ontario. This instrument shall provide for non-intrusive flow measurement, indication, totalizing, transmitting and data logging of the flow rate in a full pipe.

GENERAL:

Each portable Doppler flow meter shall have the following design features and engineering specifications:

A. PERFORMANCE SPECIFICATIONS

- Measure forward and reverse flow ± 0.1 to 40 ft/sec (± 0.03 to 12.2 m/sec).

- Have an accuracy of ±2% of full scale on most wastewater applications. Have linearity of ±0.5% and repeatability of ±0.25%.

- Operate on liquids with entrained particles or gases of 100 microns or larger and minimum concentrations of 75 ppm.

- Operate from the outside of common pipe materials including: carbon steel, stainless steel, ductile iron, copper, PVC, FRP, ABS and other selected engineering materials.

- Operate on AC/DC power.

B. TRANSDUCER

- Have a single-head, clamp-on transducer with twin piezo-electric ceramic transmit and receive crystals encapsulated in epoxy resin and a stainless steel housing.

- The transducer shall be solid state and transformer isolated, and operate at 640KHz.

- The transducer shall be waterproof and operate at temperatures from -40°F to 300°F (-40°C to 150°C), and withstand accidental submersion to 10 psi.

- The transducer shall be designed to install on pipes with inside diameter ranging from 1/2" to 180" (12.5 mm to 4.5 m).

- Have a 12 ft (3.6 m) long flexible, shielded coaxial pair cable extending from the transducer to the electronics.

- Shall include Manufacturer's recommended sensor coupling compound and adjustable stainless steel sensor mounting clamp.

C. ELECTRONICS

- Have a portable ABS electronics enclosure with a padded, watertight IP67 carrying case. Total weight shall be less than 14 lbs (6.5 kg).

- Electronics shall be designed for continuous operation at temperatures from -10° to 140°F (-23° to 60°C).

- Have a built-in 5-key calibration keypad with operator selection of parameters through visual prompts from a menu calibration system. Systems requiring calibration by Parameter codes or external calibrators shall not be accepted.

- Have user-selectable menu languages including English, French and Spanish.

- Have a white, backlit matrix display indicating flow in user-selected engineering units, totalized flow, units of calibration, and signal strength.

- Have display backlight brightness adjustment for reduced power consumption.

- Have flow proportional 4-20mA output rated to maximum resistive load of 500 ohms.

- Have a built-in 300,000 point data logger, USB output and connecting cables. Data logger shall support time and date-stamped logging and generate formatted flow reports including total, average, minimum, maximum and times of occurrence.

- Include Windows software for data log retrieval, graphing and export.

- Have automatic signal strength and signal confidence monitoring.

- Have keypad adjustable signal cutoff to reduce interference.

- Shall include an external charger with 100-240VAC 50/60Hz input.

- Shall include an internal NiMH rechargeable battery with minimum capacity for 18 hours continuous battery operation.

- Have a battery status indicator with automatic low battery shut off and battery overcharge protection.

- Have user-selectable "sleep mode" synchronized to data logger sample rate for reduced battery power consumption.

D. OPTIONAL FEATURES FOR INSERTION IN SPECIFICATION AS REQUIRED:

- Include additional 150 g. manufacturer's recommended ultrasonic sensor coupling compound.

- Include 50 ft (15 m) length Sensor Cable extension complete with connecting plugs.

PDFM5.1 Portable Doppler Flow Meter Brochure

PDFM 5.1 Brochure

PDFM5.1 Portable Doppler Flow Meter User Guide

PDFM5.1 User Guide

Doppler Flow

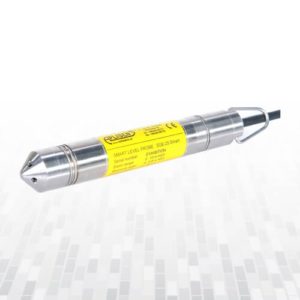

Doppler flow meters measure flow from outside a pipe with a clamp-on sensor. Greyline Doppler meters continuously transmit high frequency sound (640 kHz) that travels through the pipe wall and into the flowing liquid. Sound is reflected back to the sensor from solids or bubbles in the fluid. If the fluid is in motion, the echoes return at an altered frequency proportionate to flow velocity. Doppler flow meters continuously measure this frequency shift to calculate flow.

The Doppler effect was first documented in 1842 by Christian Doppler, an Austrian physicist. We hear everyday examples of Doppler: the sound of a train whistle changing pitch as it passes by, or the exhaust noise from a race car as it speeds past our location.

The Doppler technique only works on liquids which contain solids or gas bubbles to reflect its signal. These are "difficult" liquids that may damage regular flow meters: slurries, sludge, wastewater, abrasives, viscous and corrosive chemicals. Because the sensor mounts on the outside of the pipe, there is no pressure drop and no obstruction to flow.

For best performance Doppler sensors should be mounted away from turbulence creating devices like pipe elbows and tees, and away from velocity increasing devices like controlling valves and pumps. Typical accuracy is ±2% of full scale.

Doppler instruments include a clamp-on ultrasonic sensor, connecting cable and an electronics enclosure which can be mounted at a convenient location nearby (within 500 ft / 152 m). Sensors can be rated intrinsically safe for mounting in hazardous-rated locations.

The pipe vibrates. Will it affect the flow meter?

Answer: Common vibration frequencies are far lower than the sonic frequencies used by the Greyline flow meter, and will not normally affect accuracy or performance. However, applications where very weak Doppler signal is present (when sensitivity is adjusted to maximum and signal strength is low), accuracy may be affected by pipe vibration, or the flow meter may show readings under no-flow conditions. Attempt to relocate the sensor on a pipe section where vibration is reduced, or arrange pipe mounting brackets to reduce vibration at the sensor mounting location.

The flow meter must be installed in a high noise environment. Will this affect operation?

Answer: Greyline flow meters are designed to discriminate between environmental noise and the Doppler signal. High noise environments may affect the flow meter’s performance where low signal strength and/or low flow velocities are being measured. Relocate the sensor in a more quiet environment if possible.

Will pipe corrosion affect accuracy of the flow meter?

Answer: Yes. Rust, loose paint etc. must be removed from the outside of the pipe to provide a clean mounting position when installing a Doppler sensor. Severe corrosion/oxidation on the inside of the pipe may prevent the Doppler signal from penetrating into the flow. If the pipe cannot be cleaned, a spool piece (PVC recommended) should be installed for sensor mounting.

What effect do pipe liners have on the flow meter?

Answer: The air gap between loose insertion liners and the pipe wall prevent the Doppler signal from entering the flow. Better results can be expected with bonded liners such as cement, epoxy or tar, however an on site test is recommended to determine if the application is suitable for a Doppler flow meter.

Why is Doppler only recommended for liquids containing suspended solids or gases?

Answer: The Doppler sensor transmits sound into the flow stream which must be reflected back to the sensor to indicate flow velocity. Gas bubbles or suspended solids act as reflectors for the Doppler signal. As a guideline, Greyline Doppler flow meters are recommended for liquids containing solids or bubbles with a minimum size of 100 microns and a minimum concentration of 75 ppm. Most applications (except potable, distilled or deionized water) will meet this minimum requirement.

Can the sensor be submerged in water?

Answer: Yes, for short periods of time or by accident, but it is not recommended for continuous operation. The sensor is constructed to withstand submersion to 10 psi without damage, but external liquid moving in contact with the sensor can be interpreted as flow and cause false readings.

What is the purpose of the Signal Strength Display?

Answer: Doppler signals of very low strength are not accepted or processed by the instrument. This feature assists in rejection of environmental noise and vibration. Use the display to evaluate signal strength in your application. Strong signals will increase in percentage to a maximum of 100% or greater.

Does the PDFM 5.1 require periodic recalibration?

Answer: PDFM 5.1 calibration does not drift over time. The solid state sensor has no moving parts to wear and affect calibration. The Doppler flow technique generates an ultrasonic signal proportional to the velocity of flow. All Greyline timing/counting circuits use crystal-controlled frequency references to eliminate any drift in the processing circuitry. ISO 9000 or similar quality management systems may require periodic and verifiable recalibration of flow meters. PDFM 5.1 Doppler Flow Meters may be returned to Greyline for factory calibration and issue of a new NIST traceable certificate. Refer to the ‘Product Return Procedure’ section of this manual for return instructions.

Reviews

There are no reviews yet.