-

Read moreQuick View

Read moreQuick ViewThreaded seals with flush diaphragm and radiator S-Rc

S-Rc diaphragm seals are applicable to measurement of hot, viscous, solidifying or contaminated liquids, in any cases where an impulse line cannot be used.

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewOver Gear Flow Meter

- Accuracy: 0.5%, 0.2%

- Line size: 10~200mm

- Capability of measuring high-temperature and high-viscosity liquid

- Small pressure loss

- Simple installation

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewN-Serie Mass Flowmeters

Series N Mass Flow Sensor and IPT200 / DPT100 transmitter are paired to constitute series N flow meter with accuracy in 0.2% or 0.15%.

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewP – Serie Mass Flowmeters

P – Series Flow Meter consists of Series P Mass Flow Sensor and DPT Transmitter. The main features are as follows;

- Applied to Liquids, Gases, Grout Mass Flow

- Pipe sizes: DN10 – DN150

- Flow Measuring Accuracy: ±0.1%

- Density Measuring Accuracy: ±0.001g/cm2

- Process Temperature Limits: -40°C…+200°C

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewThermal Mass Flow Switch 7000NH – 7200NH

Switch contact closure: 5 amp at 5 VDC & 115VAC

Trip point accuracy: ± 1% of set point

Fluid temperature range: -40° to 65°C

Pressure rating, maximum: 500 PSI Std., > 500 PSI, special

Input power requirement: 24 VDC @ 250 mA max., 230 VAC 50/50 Hz optional

Flow Transmitter enclosure: IP66, 125 x 125 x 100 mm ABS plastic with polycarbonate cover

Wetted materials: All 316 SS (ceramic, glass, & epoxy optional)Read moreQuick View -

Read moreQuick View

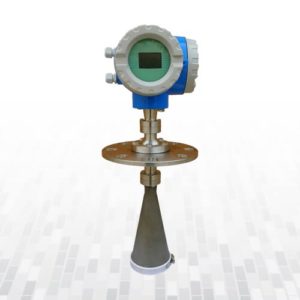

Read moreQuick ViewUltrasonic Level Transmitter ALIT-RD

- Level or Distance mode

- 4-20 mA output

- Continuous non-contact level measurement with compact version

- LC Display

- Ex-proof version

- All metal outer cover ( IP 67 ), air-proof and alkali-resisting

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewUltrasonic Flowmeter/Calorimeter TFM3100 – F1

The Transit Time Flow Meter TFM3100 measures flow rate by calculating the spreading time of an ultrasonic wave in a liquid, going upstream and downstream into a pipe.This flow meter is mostly used to measure the flow rate of homogeneous fluids, also with a quite high percentage of suspended solids.High accuracy measuring: Linearity: better than 0.5% Repeatability: better than 0.2%, Accuracy: better than ± 1%Wide measuring range: Several types of transducers to be selected, measuring pipe sizes from DN15mm to DN6000mm with four different types of sensors + PT100 ohm when it works as heat meter.Italian or English menu: The different versions of TTFM100/2009 NEW GENERATION can support Italian or English display, easy to operate, in the near future other languages will be implemented.Power supply: 8….36 VDC or 10….30VACEngineering Units: Flow: Imperial and metric – Calories: BTU; GJ; KW; KCalDimensions / Protection Grade: 90 90 36mm / IP20Set-Up: By integrated keypadOutput: Relay OCT/4-20mA/RS485Protocol: M-BUS, MODBUSRead moreQuick View -

Read moreQuick View

Read moreQuick ViewUltrasonic Flowmeter TFM4100W

Ultrasonic Flowmeter TFM4100W measures flow rate by calculating the spreading time of an ultrasonic wave in a liquid, going upstream and downstream into a pipe.This flow meter is mostly used to measure the flow rate of homogeneous fluids, also with a quite high percentage of suspended solids.Read moreQuick View -

Read moreQuick View

Read moreQuick ViewUltrasonic Flowmeter TFM5100-NG

The Transit Time Flow Meter TFM5100-NG measures flow rate by calculating the spreading time of an ultrasonic wave in a liquid, going upstream and downstream into a pipe.This flow meter is mostly used to measure the flow rate of homogeneous fluids, also with a quite high percentage of suspended solids.Read moreQuick View -

Read moreQuick View

Read moreQuick ViewUltrasonic Flowmeter TTFM100-F1-NG

The Transit Time Flow Meter TTFM100-F1-NG measures flow rate by calculating the spreading time of an ultrasonic wave in a liquid, going upstream and downstream into a pipe.This flow meter is mostly used to measure the flow rate of homogeneous fluids, also with a quite high percentage of suspended solids.•Clamp-on sensors: it is not necessary to stop the flow to install them; Wetted sensors.•AC and DC supply: 85..264 VAC and 24 VDC.•The time difference during the measuring process could be 0.2 ns.•Analog (4-20 ma), pulses (relays), frequence, Pulse (OCT) and RS485 (M-BUS, MODBUS )outputs.•All the measures could be driven to the RS485 in order to save data into a PC remotely transmitted by telemetry.Read moreQuick View -

Read moreQuick View

Read moreQuick ViewHydraulic Comparator AK7610BA

- Pressure range: 0 – 600 bar

- Stability: 0,05% F.S.

- Working media: Transformer oil

- Outpt interface: M20x1,5 Female

- Overall Dimensions: (L X W X H) 450mm x 420mm x 200 mm

- Weight: 19kg

Read moreQuick View -

Read moreQuick View

Read moreQuick ViewBT400-OX, Pressure Comparison Pump

Hydraulic Comparison Calibration Pump for the comparison calibration of pressure gauges, transmitters, switches…Type BT 400-OX: up to 400 bar / 5800 psi, for OXYGEN use, free of oilRead moreQuick View

+90 505 057 73 00 |info@debikontrol.com