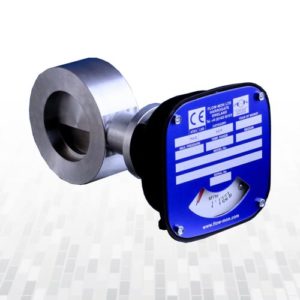

Thermal Mass Flow Meter 8000MP – 8100MP

Outputs: 4 – 20mA, 0 – 5VDC

Signal Interface: RS232 & RS485 Modbus RTU

Accuracy: +/- 1%

Gas Temperature Range: -40…+200C

Power: 24VDC 250mA

Display: 2 lines, 16 characters

Keypad: 4-buttons

Wetted Materials: 316 Stainless Steel (Hastelloy optional)

Protection: IP66

Traceable Calibration Certificate: NIST Standard

ATEX Certificate: CE 0344; EX II 2GD / EEx d IIB + H2

- Description

- Application Areas

- Reviews (0)

- Specifications

- Brochure

Product Description

Thermal Mass Flow Meter 8000MP – 8100MP sensors use two ratiometrically-matched, reference-grade platinum Resistance Temperature Detectors (RTDs). The platinum sensing element wire is wound on a ceramic base, given a thin protective glass coating, and encapsulated in a 316 Stainless Steel sheath or, if specified, a Hastelloy C sheath. The sensor assembly is large, rugged, and relatively insensitive to dirt buildup. A forced null Wheatstone Bridge preferentially heats one RTD. The second RTD acts as a temperature reference by taking on the temperature of the flowing gas. The resistance ratios are maintained through the Wheatstone Bridge to compensate for the dynamic changes in process temperature. By maintaining a constant temperature difference between the RTDs, Thermal Mass Flow Meter 8000MP – 8100MP can measure the amount of heat dissipated by the flowing gas. As heat is dissipated, more power is used to maintain the constant temperature. The power demand is directly proportional to the gas mass flow rate, allowing our sensors to measure the gas molecular rate of flow without further compensation for outside effects. Thermal Mass Flow Meter 8000MP – 8100MP’s standard flow sensors can respond to flow velocities as low as 15 feet per minute and as high as 45,000 feet per minute for most gases.

AUTOMOTIVE INDUSTRY Compressed Air monitoring * Natural Gas consumption * Powder paint air flow * Paint booth/paint oven ventilation

UTILITY SERVICES Stack or Flue Gas * Wastewater aeration * Ventilation systems * Digester Gas * Gas flows * Nitrogen purge * Combustion air * Boiler inlet air

FOOD PROCESSING Drying air * Ventilation systems * Boiler inlet air * Exhaust gas * Process control * Compressor lines * HVAC Air balancing * Duct flows * Energy conservation * Fume hoods * Cleanrooms * Laminar flow benches

LABORATORY AND R & D Flow research * Biomedical studies * University studies * Toxicology studies * Energy studies * Industrial Hygiene * Occupational Safety * Experimentation

PETROLEUM & GAS INDUSTRIES Custody transfer * Landfill Gas recovery * Flare Gas measurement * Gas mixing * Gas quality studies * Leak testing

RAW MATERIALS INDUSTRIES Pulp & Paper mills * Mining * Semiconductor manufacturing * Chemical processing * Primary metals * Plastics & synthetics

Be the first to review “Thermal Mass Flow Meter 8000MP – 8100MP”

Linear signal output : 0–5 VDC & 4–20 mA

Signal Interface : RS232 & RS485 Modbus RTU

Accuracy, including linearity (Ref.: 21°C)* : ±[1% of Reading + (.5% + .02%/°C of Full Scale)] ±0.2% of

Repeatability : Full Scale

Sensor response time : 1 second

Turn down ratio : 100:1 minimum

Electronics temperature range : -40°–85°C (-40°–185°F)

Gas temperature range** : -40°–200°C (-40°–392°F), extended range available

Gas pressure effect : Negligible over ± 20% of absolute calibration pressure

Pressure rating maximum : 500 PSI Std., > 500 PSI special

Input power requirement : 24VDC @ 250mA 115 VAC 50/60 Hz optional 230 VAC 50/60 Hz optional

Flow Transmitter power requirements : 5 watts maximum

RAM Back-up : Lithium Battery

Wetted materials : 316 Stainless Steel (Hastelloy optional)

Standard temperature & pressure (STP) : ) 70°F & 29.92" Hg (Air .075 lb./cubic foot)

NIST traceable calibration : Standard

Reviews

There are no reviews yet.